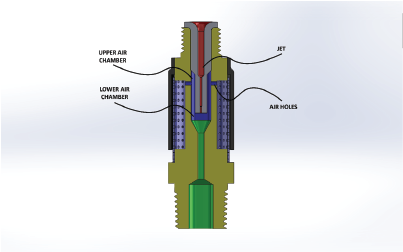

Let’s imagine we have a nozzle with a piece of debris in it, and we try to blow out the nozzle using a blow gun with compressed air. What exactly is happening? These illustrations will aid our understanding.

Blowing from the top

The last thing we want to do is blow through the nozzle from the top. If there is any type of foreign substance in the top of the nozzle, at the opening of the jet, we absolutely don’t want to blow it through or even towards the metered orifice. The jet is shaped like a funnel, and blowing air down from the top blows whatever is in the nozzle farther down into the narrow part of the jet. The better choice would be to blow through the jet in the other direction – from inside of the nozzle assembly – so that any deposits or debris are blown out, not in.

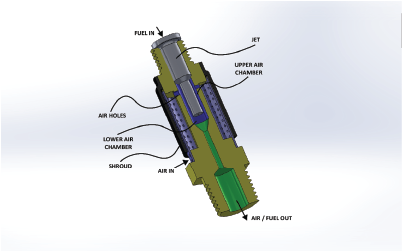

Blowing from the bottom

Now suppose we were to blow air into the assembly from the bottom. Where does the debris go now? It certainly doesn’t go out of the nozzle assembly. It’s very unlikely to come out through the small metered orifice at the bottom of the jet. Instead, the debris is much more likely to go into the upper section of the air chamber. It will get blown up around the outside of the jet, and possibly go through or clog up the air holes in the barrel. If it does go through those holes, it becomes trapped by the screen on the outside of the nozzle. But, more likely than not, it will just get wedged or impacted into the upper air chamber, and will stay there until engine vibration and air flow shakes it loose, where it will once again plug up the nozzle exit on a future flight and cause that cylinder to misfire.

In addition, the air holes on the side of the barrel are much, much bigger than the metered orifice in the jet – so when blowing air up through the bottom of the nozzle assembly, the vast majority of the pressurized air will escape through the air holes and out through the screen. A very minimal amount of compressed air will escape out through the jet, meaning any contamination in the jet itself will almost certainly not be removed.

As we can see, it’s virtually impossible to blow any debris out of the nozzle assembly using just a blow gun. We can only succeed in blowing the debris further into the nozzle assembly, where it will remain trapped.

So what now?